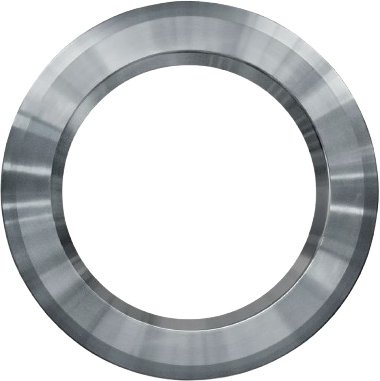

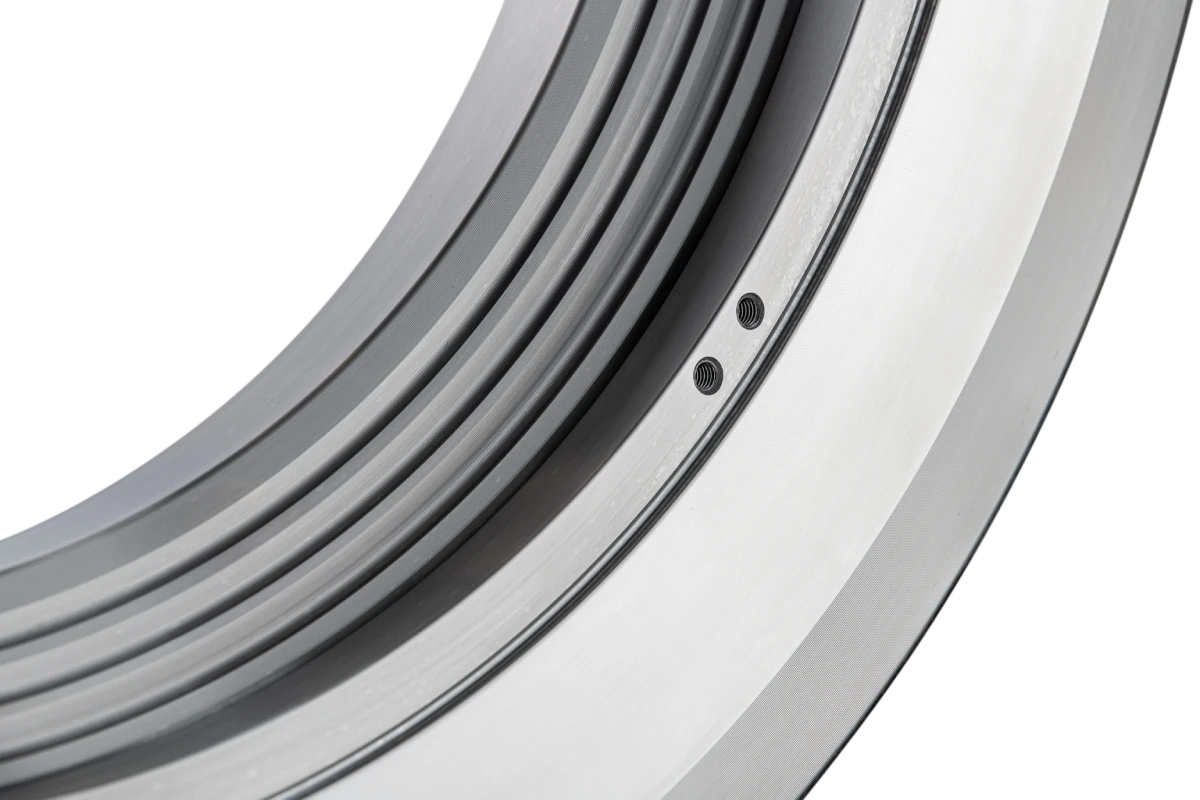

The tram wheel rims we manufacture are made from the highest quality European steel, meeting EU

requirements for strength and safety. Each rim is manufactured to order, according to the technical

drawings provided, to ensure a perfect fit to the requirements of the specific vehicle and project. In

addition, in cases where technical documentation is not available, we use reverse engineering

technology to enable exact reproduction of existing components. Thanks to the use of state-of-the-art

machining machines, our rims can reach a maximum diameter of 920 mm, offering customers a product

with reliable durability and the highest precision, suitable for intensive use in rail transport. Due to our

extensive technological facilities, we are able to handle large orders efficiently and support your project

at every stage. In the production of tram wheel rims, we offer the possibility of narrowing the hardness

spread from 320 HB on request. This change has a positive effect on extending the life of the rims,

providing greater wear resistance and long-term reliability during operation.