MANUFACTURER OF SPARE PARTS AND COMPONENTS FOR RAIL VEHICLES

MANUFACTURER OF SPARE PARTS AND COMPONENTS FOR RAIL VEHICLES

WHAT WE OFFER

In response to our customers’ needs, we supply a full cross-section of spare components and equipment necessary to maintain vehicles in optimum technical condition. Advanced technological facilities, combined with the extensive knowledge and experience of our specialists, allow us to provide solutions that meet even the most demanding expectations, standards and formal requirements. We make sure that rail vehicle transport is a safe form of urban transport. That is why we produce specialised equipment and spare parts not only for deliveries or repairs, but also for the construction of vehicles. For a complete overview of our range of products, please visit the dedicated section of our website.

01

02

03

In order to make it easier to identify components, we have prepared a dedicated tab for you “Catalog Numbers”, containing a complete list of our products with their corresponding manufacturer part numbers.

poznaj przewagę naszych obręczy

Każda obręcz wytwarzana jest na zamówienie, zgodnie z dostarczonymi rysunkami technicznymi, tak aby zapewnić idealne dopasowanie

do wymagań konkretnego pojazdu i projektu. Dodatkowo, w przypadku braku dokumentacji technicznej, stosujemy technologię

inżynierii odwrotnej, umożliwiającą dokładne odwzorowanie istniejących komponentów. Oferujemy szereg dostosowań produkcji, w

tym dokładność obróbki tak, aby w jak największym możliwym stopniu zyskać satysfakcję naszych Klientów.

Nasze obręcze produkujemy według Polskiej Normy PN-K-92016 „Obręcze obrobione – Wymagania i badania,” z zachowaniem

specyfikacji profilu zewnętrznego zgodnej z tą normą. Dzięki naszym specjalistycznym maszynom jesteśmy w stanie dostarczyć

precyzyjnie obrobione produkty spełniające nawet najbardziej wymagające normy.

Nasze produkty są oznakowane w sposób trwały i zgodny z wymogami. Znakowanie zawiera informacje o producencie, materiale, roku

produkcji, a także wyniki testów, takie jak twardość i klasa wytrzymałości na rozciąganie. Na specjalne życzenie możemy również nanieść

dodatkowe oznaczenia techniczne na bieżni obręczy. Dostarczamy pełną dokumentację jakościową dla każdej partii wyprodukowanych

obręczy, w tym świadectwa hutnicze oraz protokoły zdawczo-odbiorcze. Dla elementów metalowych (i gumowych) oferujemy pełne

zestawienie wyników wewnętrznych kontroli jakości, zgodnie z normą PN EN 10204:2006.

Udzielamy gwarancji na okres 12-24 miesięcy, w zależności od specyfiki projektu, z zapewnieniem wsparcia w razie potrzeby. Oferujemy

także możliwość długoterminowej współpracy na zasadach sukcesywnych zamówień i elastyczne dostosowanie harmonogramu prac i

dostaw do potrzeb naszych klientów.

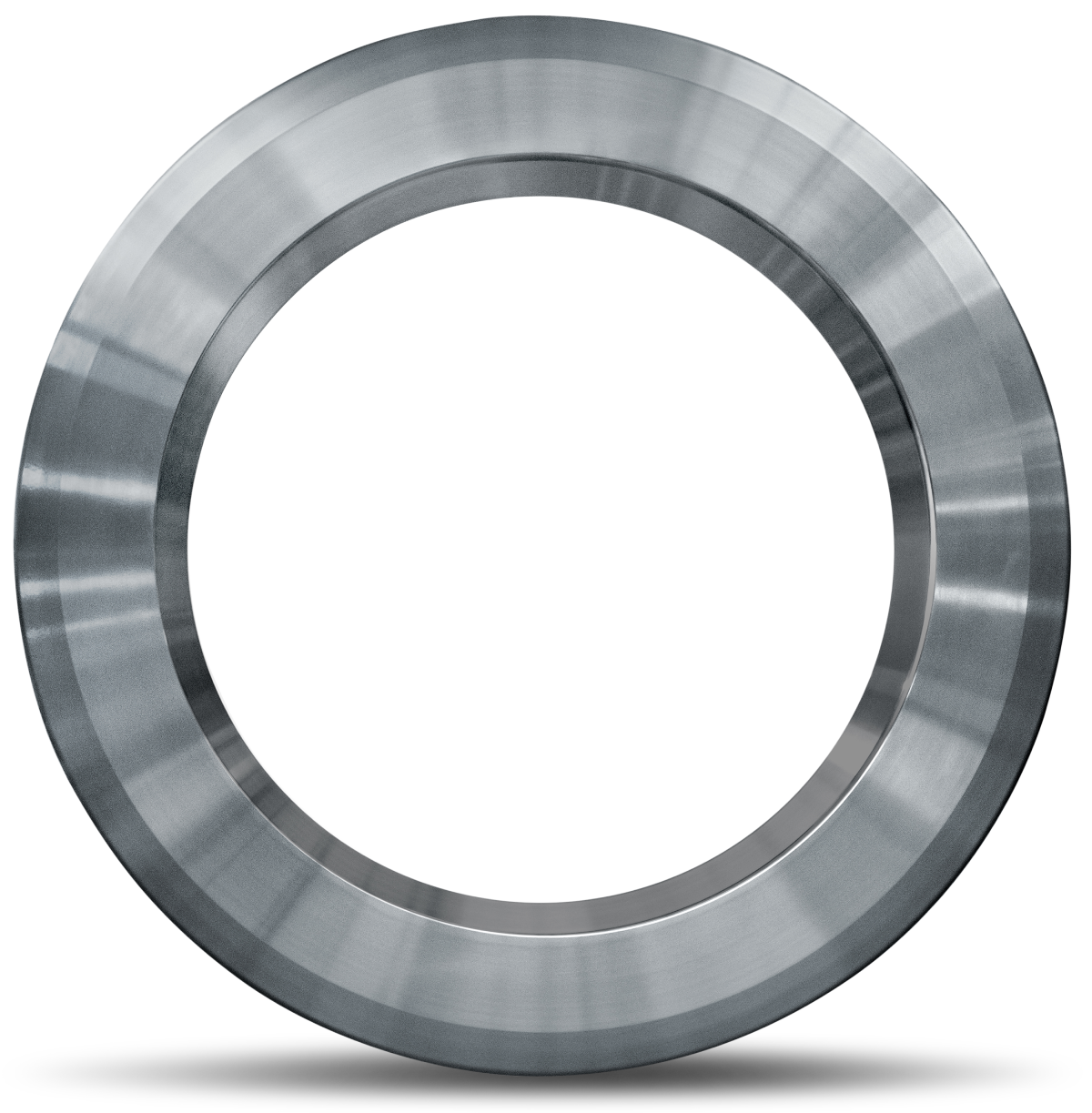

DISCOVER THE ADVANTAGES OF OUR RIMS

QUALITY AND PRECISION WITHOUT COMPROMISE

Each rim is manufactured to order, according to the technical drawings provided, to ensure a perfect fit to the requirements of the specific vehicle and project. In addition, in the absence of technical documentation, we use reverse-engineering technology to enable exact reproduction of existing components. We offer a range of production adjustments, including machining accuracy so as to gain our customers’ satisfaction as much as possible.

DISCOVER THE ADVANTAGES OF OUR RIMS

COMPLIANCE WITH INDUSTRY STANDARDS

Among other things, we manufacture our rims according to the Polish standard PN-K-92016 “Machined rims – Requirements and tests,” with the outer profile specification compliant with this standard. Thanks to our specialised machinery, we are able to deliver precisely machined products that meet even the most demanding standards.

DISCOVER THE ADVANTAGES OF OUR RIMS

INDIVIDUAL LABELLING AND DOCUMENTATION

Our products are marked in a permanent and compliant manner. The marking includes information about the manufacturer, material, year of manufacture, as well as test results such as hardness and tensile strength class. On special request, we can also apply additional technical markings to the rim raceway. We provide full quality documentation for each batch of rims produced, including metallurgical certificates and delivery and acceptance protocols. For metal (and rubber) components, we offer a full summary of the results of internal quality checks in accordance with PN EN 10204:2006.

DISCOVER THE ADVANTAGES OF OUR RIMS

LONG-TERM GUARANTEE AND SUPPORT

We provide a guarantee for a period of 12-24 months, depending on the specifics of the project, with support provided if required. We also offer the possibility of long-term cooperation on the basis of successive orders and flexible adjustment of the work and delivery schedule to the needs of our clients.

01

QUALITY AND PRECISION WITHOUT COMPROMISE

Each rim is manufactured to order, according to the technical drawings provided, to ensure a perfect fit to the requirements of the specific vehicle and project. In addition, in the absence of technical documentation, we use reverse-engineering technology to enable exact reproduction of existing components. We offer a range of production adjustments, including machining accuracy so as to gain our customers’ satisfaction as much as possible.

02

COMPLIANCE WITH INDUSTRY STANDARDS

Among other things, we manufacture our rims according to the Polish standard PN-K-92016 “Machined rims – Requirements and tests,” with the outer profile specification compliant with this standard. Thanks to our specialised machinery, we are able to deliver precisely machined products that meet even the most demanding standards.

03

INDIVIDUAL LABELLING AND DOCUMENTATION

Our products are marked in a permanent and compliant manner. The marking includes information about the manufacturer, material, year of manufacture, as well as test results such as hardness and

tensile strength class. On special request, we can also apply additional technical markings to the rim raceway. We provide full quality documentation for each batch of rims produced, including

metallurgical certificates and delivery and acceptance protocols. For metal (and rubber) components,

we offer a full summary of the results of internal quality checks in accordance with PN EN 10204:2006.

04

LONG-TERM GUARANTEE AND SUPPORT

We provide a guarantee for a period of 12-24 months, depending on the specifics of the project, with support provided if required. We also offer the possibility of long-term cooperation on the basis of successive orders and flexible adjustment of the work and delivery schedule to the needs of our clients.

MORE ABOUT TIS TRAM

For more than 10 years

Co-creating the future of urban transport in Poland and abroad

TIS TRAM, before becoming an independent company, functioned as a division of the Polish welding wire manufacturer TYSWELD. In response to our dynamic growth, an increasing number of contracts dictated by the high quality of our products, we decided to create a separate entity. Our aim was to fully focus on the specifics of the rolling stock market in order to respond even more effectively to our customers’ needs. This transformation has enabled us to make better use of resources, adapt more quickly to changing trends and further develop our technology, which in turn has allowed us to become a recognised industry leader.

Our tram wheel rims are synonymous with reliability and superior quality, based on years of experience and innovative production technologies. Using only European raw materials from reputable suppliers, we create products with exceptional precision and wear resistance, which are perfect for the tough conditions of urban transport.

ABOUT US

We are a Polish manufacturer of specialised parts and components for rail vehicles, supplying a full range of components necessary to maintain the optimal technical condition of machines. We respond to the needs of tramway rolling stock operators and vehicle manufacturers who trust our knowledge and experience. Our speciality is tram rims and key components that ensure the highest quality, durability and reliability in operation.

COMPANY NEWS

CONTACT US

Always on the right tracks with TIS TRAM – Get in, relax and get in touch!