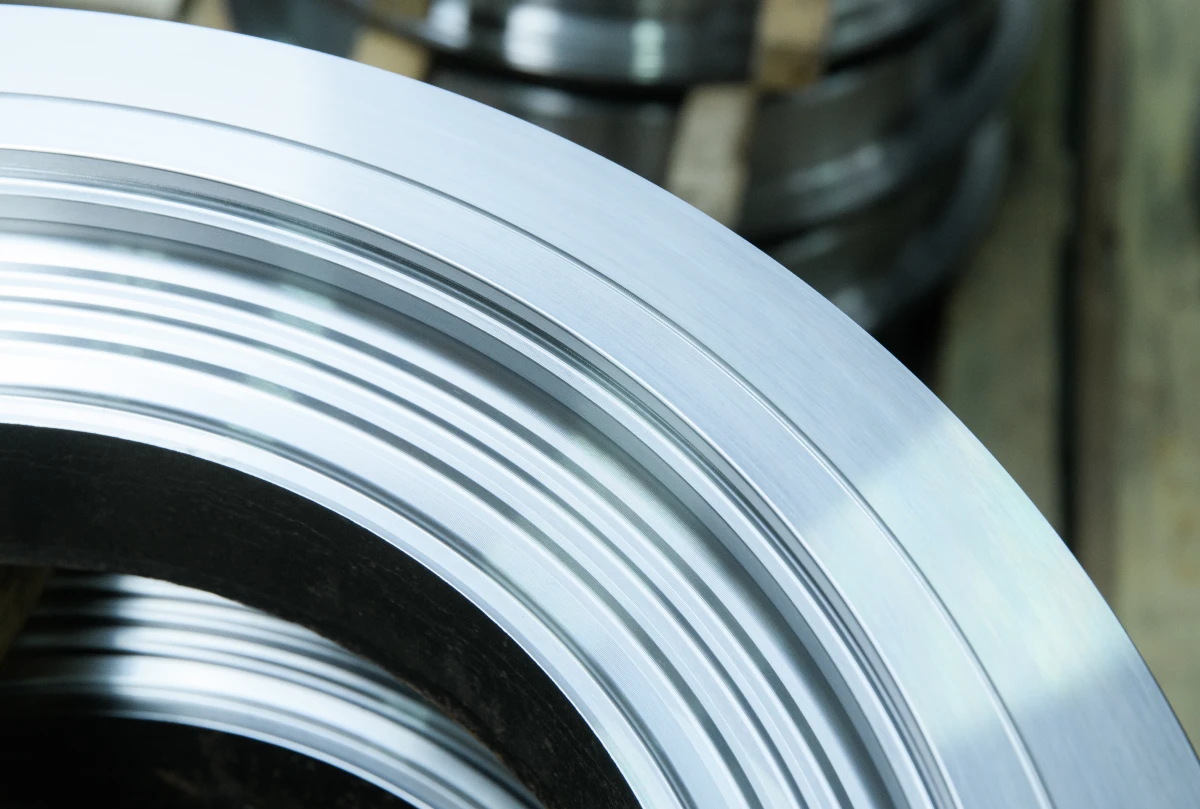

The re-profiling of tram rings is a precision machining process aimed at reconditing the proper rolling profile of tram wheel rings. As a result of use, wear, deformation and unevenness occur, which affect driving comfort, noise level and safety.

During the re-profiling:

the worn-out material layers are removed from the rolling surface and the proper ring shape is restored following applicable standards (e.g. UIC, PN, DIN). The symmetry, proper rail-track angles and required fillet raceway are ensured.

This treatment extends the life cycle of the wheelset, reduces rail-track wear, minimises the risk of derailment and improves the vehicle overall operation.

At TIS TRAM, we use modern technological solutions that guarantee high repeatability, accuracy and compliance with the customer’s technical documentation.

The re-profiling is not just machining – it is an element of prevention that has a real impact on the safety and economy of the entire transport system.

Contact us to learn more about our tram rim reprofiling service and how we can help maintain the highest quality standards of your rolling stock.